Your Partner in Quality Metal Finishing

South Haven Finishing provides all of your metal finishing needs: Polishing, Buffing, Satin Finishing, Deburring, Shot-Blasting and more. Our team has over 30 years of experience executing quality metal finishing services for Michigan businesses and beyond.

Why South Haven Finishing

Quality

With attention to detail and stringent quality expectations, our team of professionals gets the job right the first time.

Fast & Flexible

Small enough to be nimble, but big enough to get the job done. We’ve been serving Michigan companies for over 30 years.

Reliable Delivery

We’ll get you your product on time, because we understand that our reliability is your reliability. We provide delivery through our own truck, or we work with your prefered shipment service.

ISO 9001:2015

South Haven Finishing has gone through the rigorous documentation process to obtain and maintain our ISO 9001:2015 certification, validating our longstanding dedication to quality services that meet or exceed customer expectations.

Company We Keep

Metal Finishing Capabilities

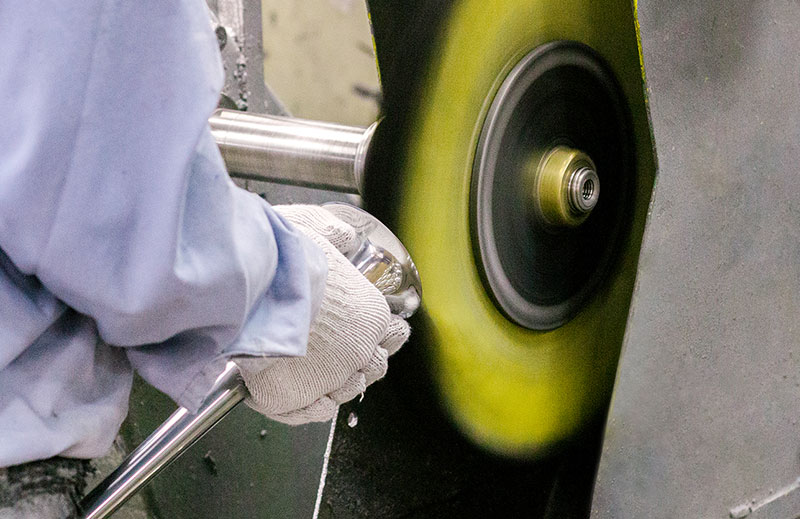

Polishing

Utilizing polishing wheels with abrasive material, we smooth and remove metal from the surface leaving shiny metal as a final functional finish or in preparation for the next finishing step, like paint, anodization, or bright buffing.

Buffing

We smooth the surface metal with an abrasive compound on a buffing wheel to reach a specific finish. Our bright buffing technique brings the part to a shiny, chrome-like appearance. This technique is often used to prepare a part for chrome plating, clear coating, or a final bright finish.

Satin-Finishing

Our abrasive Scotch-Brite brushing wheels smooth and blend polish lines to leave a smooth, lustrous brushed nickel look. This look is popular in the hardware industry. Satin finished aluminum parts can be anodized to protect the surface to ensure long-lasting finish.

Deburring

We mechanically deburr parts with aggressive materials by polishing, shot-blasting and satin-finishing to quickly remove all sharp edges. We work with you to develop a cost effective solution that meets your desired finish.

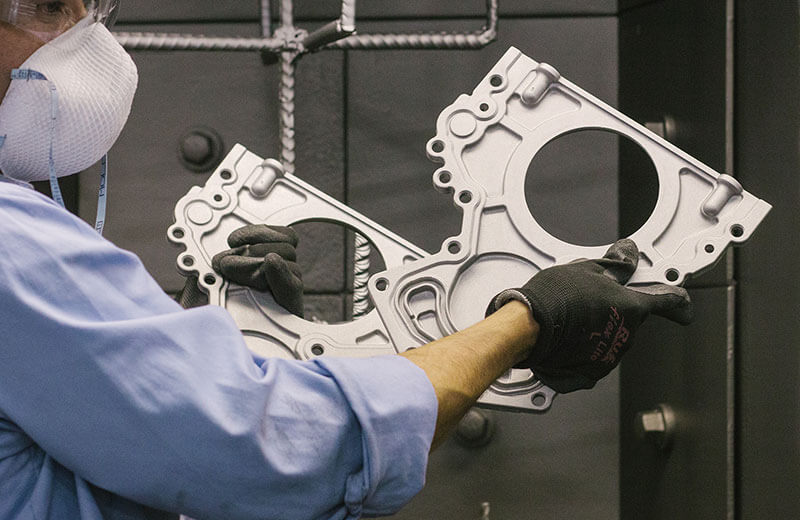

Shot-Blasting

Shot Blasting removes burrs, excess flash and sharp edges to prepare parts for paint or as a final finish. We use steel S170 virgin material shot in our shot blasting machines so the shot blasted finish is consistent. Our shot blasted finish can be adjusted to suit your finishing needs and can be used a final, stipple finish.

Custom Finishing

Our experienced team can help you achieve the luster you’re looking for. We’ll work with you to develop or choose the right process for your product or prototype.